Technical Grade Foams

Our Fire Retardant foam is approved with UL 94 HF 1 & FMVSS 302 Standards. This is a self-extinguished foam when is exposed to fire & can work in high temperatures

Densities available

FR – 23, 26, 32,40 & other densities can be developed.

L + FR – 18, 23, 24 & other densities can be developed.

Applications

High end car seats, Car roof, DG Sets, Movie theatres etc.

Fire Retardant Foams– Specifications sheet

| Characteristics | Foam Variant | Test Method | Test Standard | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Variety | 18LFR | 23L/FR | 24L/FR | 24FR | 26FR | 30FR | 32FR | 40FR | NA | NA |

| Denisity(+/-) Kg/m3 | 18(±1) | 23(±1) | 24(±1) | 24(±1) | 26(±1) | 30(±1) | 32(±1) | 40(±2) | IS:7988-1976 | IS:7933-1975 |

| 1LD at 40% (Kg) | MIN 10 | MIN 13 | MIN 15 | 15-19 | MIN 13 | 18-22 | MIN 19 | MIN 19 | IS:7988-1976 | IS:7933-1975 |

| Load Quotient | MIN 2 | MIN 1.9 | MIN 1.9 | MIN 1.9 | MIN 1.9 | MIN 1.9 | MIN 1.9 | MIN 1.9 | IS:7988-1976 | IS:7933-1975 |

| Tensile | MIN 1 | MIN 1 | MIN 1 | MIN 0.8 | MIN 1 | MIN 0.8 | MIN 1 | MIN 1 | IS:7988-1976 | IS:7933-1975 |

| Elongation(%) | MIN 120 | MIN 100 | MIN 110 | MIN 120 | MIN 100 | MIN 120 | MIN 120 | MIN 90 | IS:7988-1976 | IS:7933-1975 |

| Resilience(%) | MIN 35 | MIN 30 | MIN 30 | MIN 40 | MIN 40 | MIN 40 | MIN 40 | MIN 50 | ISO 8307 | NA |

| Flammability Standard | FMVSS 302 | FMVSS 302 | FMVSS 302 | FMVSS 302 | UL94 HF-1 | FMVSS 302 | FMVSS 302 | UL94 HF-1 | NA | |

Our Lamination foam has high bonding strength with minimum thickness loss. We have best Cell structure & less porosity to achieve good Mechanical strength. Our state of art testing lab helps to supply perfect material to our customers. This foam can be used in flame / Glue lamination & the peeled foam is sent to customer in both rolled & compressed roll form.

Densities available

18, 20, 23, 26, 36 & densities can be developed as per customer requirement.

23 & 24 are available in Lamination + FR variant also

Applications

Car Seat Covers, Helmets, Bags, Movie theatre seats, Footwear, Jackets, Caps etc.

Lamination Foams - Specifications

| Characteristics | Foam Variant | Test Method | Test Standard | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Variety | 18HL | 18L | 20L | 23L | 26L | 32L/UV | 36L | NA | NA |

| Denisity(+/-) Kg/m3 | 18(±1) | 18(±1) | 20(±1) | 23(±1) | 26(±1) | 32(±1) | 36(±1) | Physical Weightment of Sample as per IS:7888-1976 | IS:7933-1975 |

| 1LD at 40% (Kg) | MIN 14 | MIN 11 | MIN 15 | MIN 14 | MIN 13 | MIN 12 | MIN 26 | ILD at 40% Compression as per IS:7888-1976 | IS:7933-1975 |

| Load Quotient | MIN 2.0 | MIN 2.0 | MIN 2.0 | MIN 2.0 | MIN 2.0 | MIN 2.0 | MIN 2.0 | ILD at 65% Compression as per IS:7888-1976 | IS:7933-1975 |

| Tensile | MIN 1.4 | MIN 1 | MIN 1.2 | MIN 1.2 | MIN 1.2 | MIN 1.2 | MIN 1.2 | Breaking Load – dumbled shaped sample as per IS:7888-1976 | IS:7933-1975 |

| Elongation(%) | MIN 80 | MIN 100 | MIN 80 | MIN 80 | MIN 120 | MIN 100 | MIN 75 | Breaking Load – dumbled shaped sample as per IS:7888-1976 | IS:7933-1975 |

| Resilience(%) | MIN 30 | MIN 30 | MIN 30 | MIN 30 | MIN 35 | MIN 35 | MIN 30 | Ball rebound from the sample | NA |

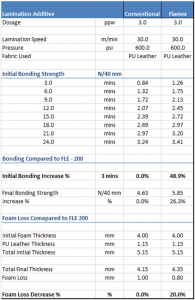

Bonding Strength

FlameX Vs Conventional Foam

- Since initial bond strength is much higher, in # 2, the lamination speed can be increased

- This will lead to further saving in Foam Loss in flame lamination and increase output

These specialty foams are manufactured to avoid paling &discoloring and stay white in spite of exposure to atmospheric elements. Paling is occurred due to oxidation in atmosphere

Densities available

32 & densities can be developed

Applications

Clothing, Lingerie, Sports Shoe

These foams are electrically conductive & while transportation electronic components releases electrostatic from them. This foam does not accumulate electrical charge & offers protection against shock & vibrations

- Antimicrobial & Antifungal Foam – Application Hospital purposes etc.

- Ortho foam (Hard Foam) – Application in Footwear & Helmets

- Acoustic Foams – Application in Sound Proofing, Packaging.

- Rebonded Foam – Application in Car mats, Carpets & other Hard applications

- Memory Foams – Application in Mattress toping & Quilting.

- Scrubbing foam – Anti microbial treated specialty foam that passed the washing test